Seed cleaner Mahlknecht – Efficient, Precise and flexible seed cleaning machine

The Mahlknecht Seed Cleaner is a robust and high-performance machine designed for the thorough cleaning, calibration, and grading of seeds, grains, oilseeds, legumes, and hulled crops. Capable of pre-cleaning up to 12 t/h and fine-cleaning up to 1 t/h, it ensures consistently high-quality output for farms, seed producers, direct marketers, seed processors, and oil mills / oil producers.

Over 100 sieve options for precise calibration and cleaning, the machine can be precisely adapted to different seed types and production requirements. It can also be combined with additional sorting units, trieur systems, conveyor components, or installed as a mobile system, providing maximum flexibility for custom production lines.

Its durable construction guarantees reliable, long-term operation, while compact design options allow for easy integration into existing facilities. The Mahlknecht Seed Cleaner reduces impurities, improves product uniformity, and increases overall efficiency – making it an essential tool for small, medium, and industrial-scale operations.

Whether you are producing seeds for sale, oil milling, or direct marketing, the Mahlknecht Seed Cleaner delivers consistently clean, uniform, and high-quality results. Contact us for customized solutions, technical consultation, or a tailored production setup.

- Seed capacity: Pre-cleaning up to 12 t/h*; Fine cleaning: up to 1 t/h*

- Motor power: 3 kW

- Voltage: 230 V 3-phase | 400–480 V 3-phase

- Dimensions (L×W×H): 1839 × 1284 × 1898 mm

- Weight: approx. 810 kg

- Air consumption: approx. 2600 m³/h

*depending on seed type, moisture content, and application

- Internal suction fan: ~2600 m³/h

- Motor protection integrated in the machine (0/1 emergency stop switch)

- 2 sieves + frames

- Electrical connection cable (plug-ready)

- Various sieve options (more than 100)

- Built-in fine dust filter

Cleaning and grading of seeds/grains:

Cleaning and grading of seeds, grains, oilseeds, hulled fruits, and legumes such as: wheat, rye, corn, buckwheat, oats, millet, barley, sunflower, peas, rice, and more on request.

Ideal for agriculture, direct sales, seed propagation, seed processing, and oil milling.

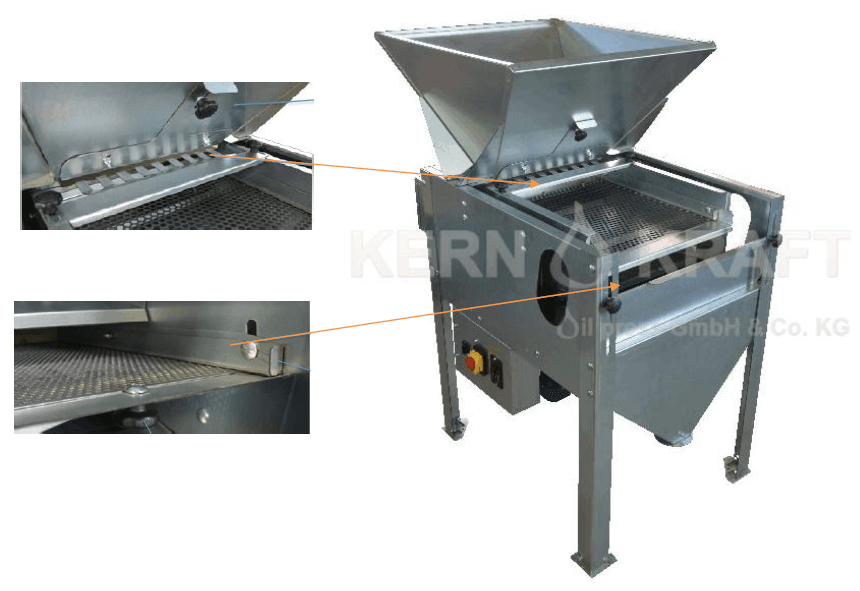

Cerpur Seed and Grain Cleaner – Premium engineering for efficient seeds processing

The Cerpur Seed and grain cleaner is a compact, versatile, and high-performance machine designed for the precise cleaning and calibration of seeds, grains, and oilseeds prior to pressing, milling, or other processing steps. With a processing capacity of 200–1,000 kg/h, depending on seed type and desired quality, it guarantees consistently clean raw materials for optimal downstream results.

Built with robust engineering, the seed cleaning machine Cerpur combines durability, precision, and efficiency, making it ideal for small to medium-scale operations that demand reliable performance. Its compact footprint allows seamless integration into existing production lines without compromising on throughput or quality.

Efficient seed and grain cleaning to remove impurities and ensure uniform product

Automation-ready with dosing hopper and conveyor options for continuous operation

Compact, robust design for easy installation and long-term reliability

Perfect for seed processing facilities, agricultural operations, oil mills, and artisanal producers, the Cerpur Seed and Grain Cleaner guarantees clean, calibrated raw materials while saving time and improving efficiency.

- Seed capacity: 200 to 1000 kg/h*

- Motor power / Voltage:

- Fan: 0.09 kW | 230 V 50 Hz | speed adjustable

- Sieve motor: 0.09 kW | 230 V 50 Hz | speed adjustable

- Dimensions (LxWxH): 1080 × 720 × 1360 mm

- Weight: approx. 95 kg

*depending on seed type and cleaning quality

- On/Off switch and safety switch

- Feed hopper: 114 L

- 2 sieve boxes with (eccentric) tapping device and adjustable inclination

- Seed slide with bridge breaker

- Plug-ready (Schuko plug)

- Currently 55 sieve options (in stock)

Cleaning of seeds, cereals, and oilseeds before pressing, milling, and other processes.

oil press GmbH & Co. KG

Alfrased 1

84367 Reut/Ndb

Germany

Tel.: +49 (0) 8574 535

Fax: +49 (0) 8574 9199861

E-Mail: info@oelpresse.de